YP Type Conductive Rubber Connector

YP type Zebra Connectors are supported by a sponge foamed insulating silicone layer on both sides of the zebra layer to meet more applications where insulation is critical. At the same time, the foam layer is very soft, so in practical applications only a small compressive force is required to achieve good contact performance.

Zebra Connectors Naming Conventions

To ensure that zebra connectors are made correctly, the naming specifications are as follows:

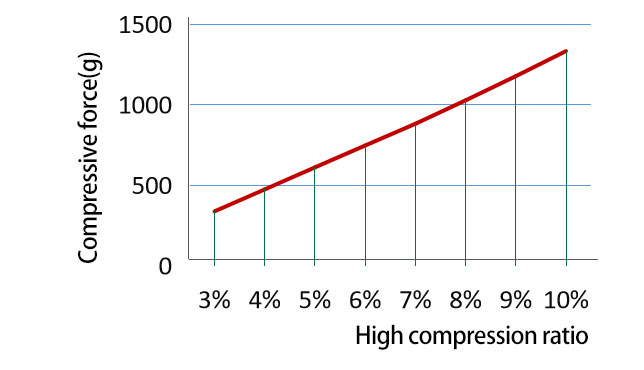

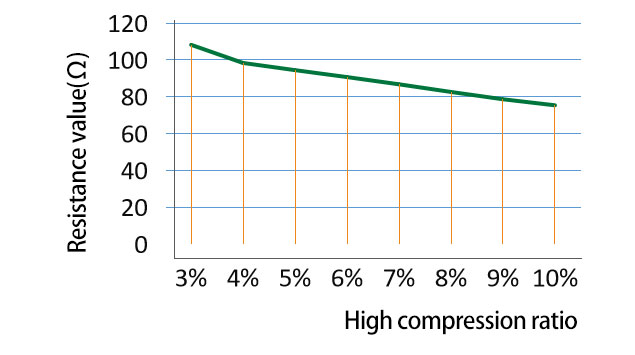

Preload relationship and curve

The superior elasticity of conductive rubber connectors can effectively avoid the risk of good contact with components due to aging deformation and accidental drop of structural parts during the use of electronic equipment, but with the deformation of structural parts and the change of compression force, the compression ratio and resistance of conductive rubber connectors will also change, and it is necessary to fully consider when setting structural parts and conductive rubber connectors. As follows:

The calculation of conductive rubber connector resistance can be referenced by the following formula:

R = Resistance value (Ω)

CW = Conductive width (mm)

L = Conductive length (mm)

H = Conductive height (mm)

ρ = volume resistivity (Ω·cm)

The calculation of the compressive force of a conductive rubber connector can be calculated by reference to the following formula:

F = Press pressure (g)

D = Compression ratio D = (H-H1) ÷ H

E0 = Zebra layer modulus of elasticity 3.5MPa

E1 = Modulus of elasticity of the insulation liner 1.7MPa

H = Conductive rubber connector height (mm)

W = Conductive rubber connector width (mm)

CW = Zebra Layer Width (mm)

W1 = Insulation liner width (mm) W2 = W-W1

L = Conductive rubber connector length (mm)

Structure and electrical performance data

Implementation standard: GB2439, GB/T528

| Project | Specification values | |||

| Material | Conductive layer | Insulation layer | Foam lining | |

| Conductive silicone rubber | Silastic | Silastic | ||

| Routine | Low resistance | Routine | Routine | |

| Hardness(A) | 65±5 | 70±5 | 65±5 | 40±5 |

| Volume resistivity(Ω·cm) | <6 | <3 | >1012 | >1012 |

| Tensile strength(mPa) | >4 | >5 | >4 | >4 |

| Elongation(%) | >100 | >150 | >100 | >300 |

| Tear strength(N/mm) | >8 | >12 | >10 | >12 |

| Color | Black | White | Pink | |

Work environment data

| Operating temperature | Operating humidity(%)25℃ | Maximum operating current (mA/mm2) | |

| Minimum | Maximum | ||

| -50 | 150 | 85 | 2.5 |